MIG Maintenance Software

Efficiency, finally made simple.

Maintenance software for planning and managing preventive and corrective maintenance, inventory and resource management, and statistics on key maintenance indicators.

Request a demo with Giacomo

Friendly, no sales pressure.

MIG

CMMS with Italian Excellence.

With over 30 years of experience in the industry, TAM Software is the ideal partner for your business. The triad of MIG is essential for effective maintenance management across all sectors.

With MIG you can:

-

Plan and control all maintenance activities, both routine and extraordinary, from a single platform.

-

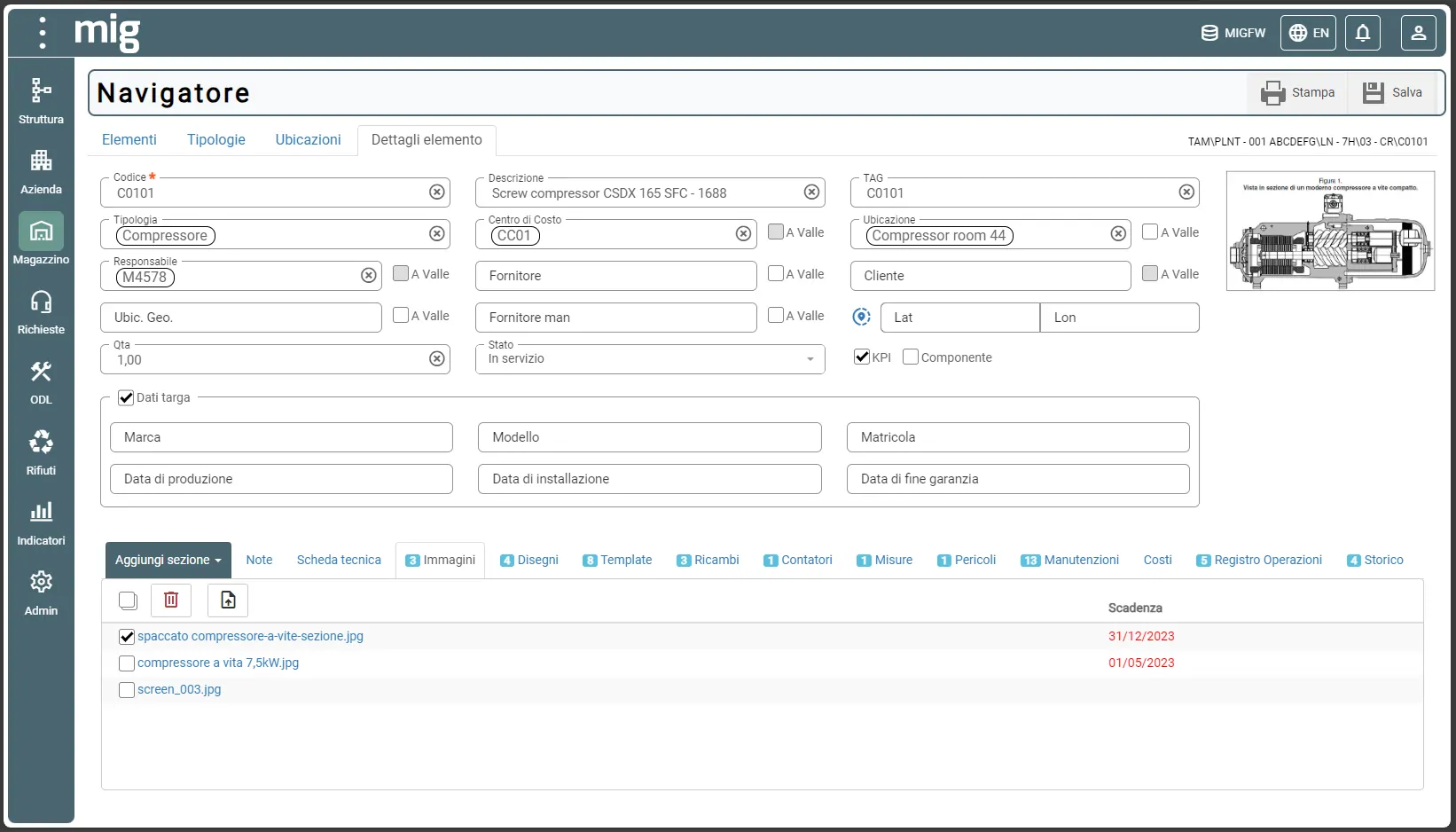

Manage assets, facilities, and equipment with information that is always up to date and easily accessible.

-

Assign and monitor interventions in real time, improving response times and operational efficiency.

-

Reduce downtime and unexpected costs through more preventive and less reactive maintenance.

-

Gain a clear and immediate overview of priorities, activity status, and the resources involved.

Maintenance

The MIG Maintenance Software provides a comprehensive technical archive, enabling the management of all maintenance activities.

It places a strong emphasis on workplace safety and offers precise tools for cost control and inventory management.

With a detailed overview of KPIs, companies can monitor and improve their maintenance management performance.

Integrated

The MIG Maintenance Software integrates seamlessly with your existing software to optimize data flow and enhance communication between systems across your organization.

It offers customizable integration with ERP, SCADA, and inventory systems for maximum efficiency.

Experience the ease of integrating MIG CMMS with your current business systems.

Global

The MIG Maintenance Software allows you to manage maintenance operations from anywhere, thanks to its compatibility with smartphones, tablets, and desktop workstations.

Its flexibility enables use in both cloud environments and dedicated servers within the client’s IT infrastructure.

Adaptable to your needs, it manages maintenance in any context.

Everything You Need

Key Features

The software offers a simplified interface designed for use across your entire workforce, ensuring accessibility for all work environments.

We leverage technology to streamline and enhance maintenance operations.

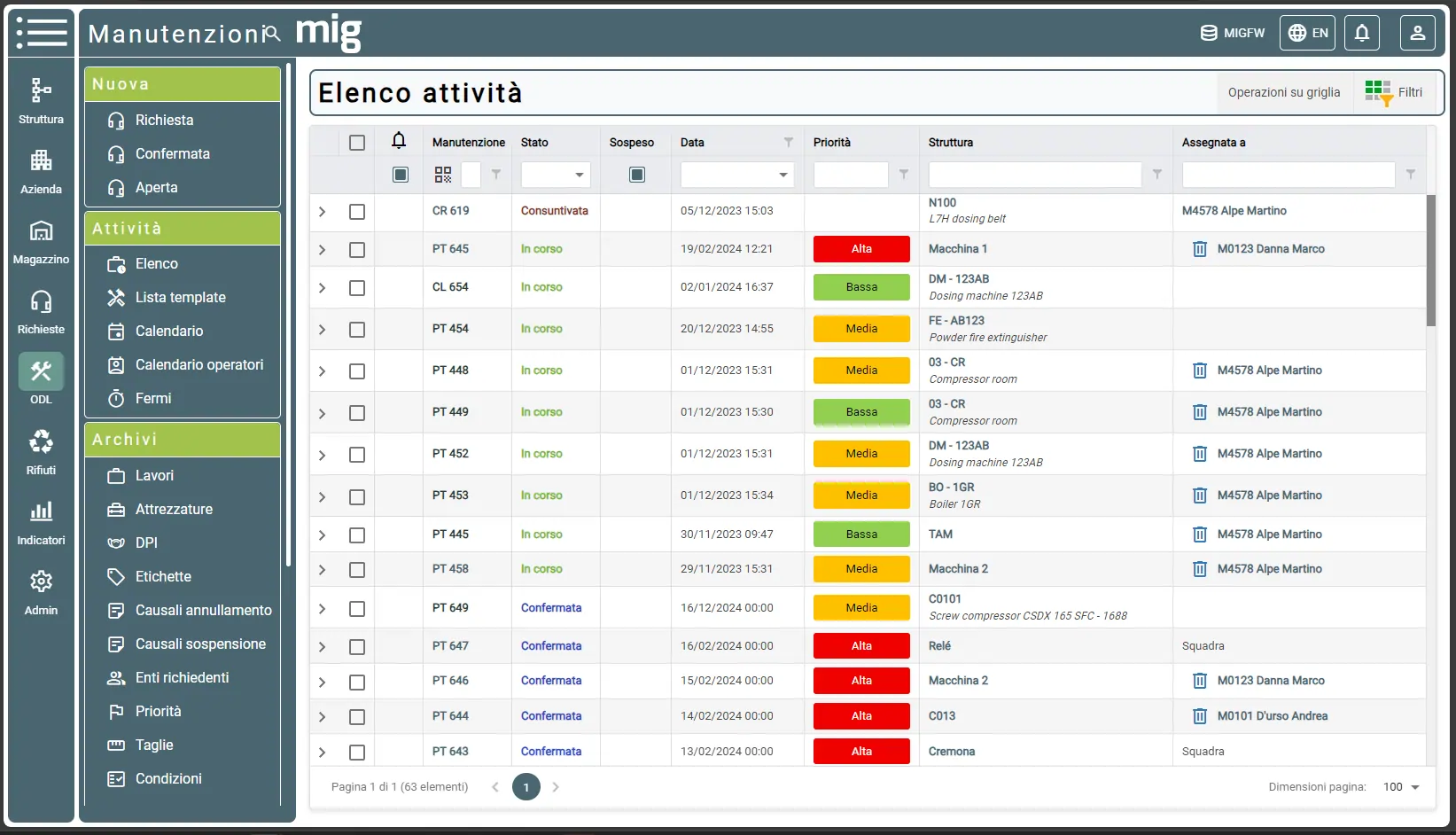

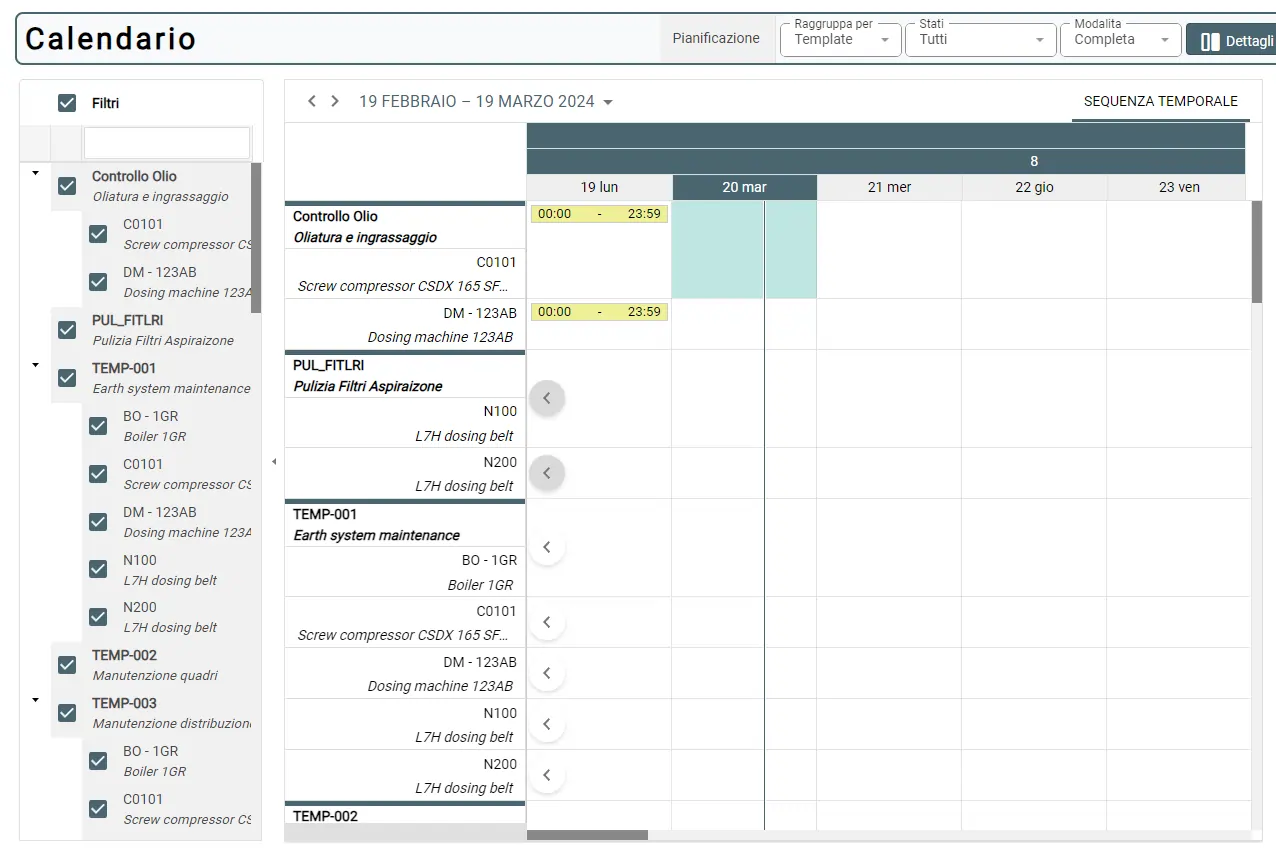

To-Do Activities: Keep track of tasks with various views: list, calendar, and dashboard.

Maintenance Activity Logging: Record critical details, including used spare parts, staff hours worked, and costs.

QR Code/NFC Tag Scanning: Quickly access information and log maintenance activities.

Access to Technical Information: Easily find data on machines and spare parts, even on tablets and smartphones.

Integrated Ticketing System: Report and manage issues efficiently from anywhere.

Secure Access: Access control and password security both within the company network and externally with SSL certification.

Ten answers before getting started

blank

1) What are the main advantages of using a CMMS software?

The main advantages include better maintenance planning, increased operational efficiency, reduced maintenance costs, and longer asset lifespan.

2) How can a CMMS software improve operational efficiency?

A CMMS software can improve operational efficiency by optimizing maintenance scheduling, automating maintenance processes, improving resource management, and facilitating communication and collaboration between teams.

3) What are the key features to look for in a CMMS software?

Key features include work order management, preventive maintenance scheduling, spare parts inventory management, maintenance activity tracking, and reporting and analytics capabilities.

4) How can a CMMS software help reduce maintenance costs?

A CMMS software can reduce maintenance costs by optimizing activity scheduling, minimizing unplanned downtime, improving resource management, and optimizing the use of spare parts.

5) What is the role of preventive maintenance in a CMMS software?

Preventive maintenance helps identify and resolve issues before they become costly failures, contributing to keeping assets in optimal condition and reducing unplanned downtime.

6) How is the integration of a CMMS software with existing systems handled?

The integration of a CMMS software with existing systems is achieved through data import, interfacing with other enterprise software, and the adoption of communication standards such as APIs.

7) What are the common challenges in implementing a CMMS software and how can they be overcome?

Common challenges include resistance to change, lack of technical skills, legacy data management, and the need for careful implementation planning.

8) How can a CMMS software improve data traceability and management?

A CMMS software improves data traceability and management through detailed recording of maintenance activities, centralized data storage, and the generation of detailed reports.

9) How can a fully customizable CMMS software adapt perfectly to company workflows?

A fully customizable CMMS software can adapt perfectly to company workflows by allowing the configuration of modules, fields, and processes based on specific business needs.

10) How can a CMMS software improve workplace safety?

A CMMS software can improve workplace safety by managing safety inspections and tests, scheduling preventive maintenance activities, and tracking maintenance activities related to safety.

Close FAQ

Schedule your free consultation today!

Complete maintenance management, integration with business systems, and access from all devices — all with MIG Maintenance Software.

We’ll introduce you to the world of MIG, where we’ve harnessed technology to streamline and enhance your maintenance operations.

EXPERIENCES FROM SOFTWARE USERS

Reviews from OUR customers

Michela Roberti

— Manufacturing company

![]()

With TAM, we have finally centralized all maintenance into a single system. Intervention planning is clearer, response times have improved, and today we have a complete view of plants and activities. A concrete support for daily operations.

Graziano Romelli

— Multi-site industrial group

![]()

We were looking for a reliable, flexible CMMS that could be integrated with our corporate systems. TAM software fit perfectly into our IT infrastructure, simplifying workflows and improving coordination between departments.